Our Design Facilitation Process

At IDS, we take sign design seriously. We use several dynamic approaches including collaborating with area architects, environmental graphic designers, and end users to ensure their sign design intent is met.

Plan – The Strategy Report

Before starting we take a hard look at best practices precedents and technology changes. This is followed by recommendations and discussions through strategy reports that support the foundation for design development. The Strategy Report is flexible to the specific project and client; and can be freestanding or incorporated into larger project reports.

For The Performing Art Center at the Eastman Kodak Center in Rochester, NY, we worked with the Kodak team, General Contractor LeChase and architects SWBR to explore different approaches for the façade utilizing projection mapping, digital boards, light boxes and graphics. IDS later created the visuals that would be part of Kodak’s larger report and eventually fabricated the final project based on the architect’s final recommendations.

![636406734113344450-AX8A6167[1] Design Facilitation of the Kodak Center](https://idsignsystems.com/wp-content/uploads/2020/02/636406734113344450-AX8A61671-scaled.jpg)

Design – The Visioning Stage

Designers and End-Users often need additional support to their conceptual ideas that require additional validation and explorations. To aide in design facilitation, IDS has assembled a team that uses advanced mapping and modeling software to create a clear visual approach that can advance the design development process.

For Marywood University in Scranton, PA, a brand-conscious college developing a new highway gateway sign. IDS worked to fulfill their vision with simple and quick sketch montages and then with full renderings to study both day and evening views. IDS can complete this work in a matter of hours and often as part of a live workshop approach.

Design – The Visioning Stage

Designers and End-Users often need additional support to their conceptual ideas that require additional validation and explorations. To aide in design facilitation, IDS has assembled a team that uses advanced mapping and modeling software to create a clear visual approach that can advance the design development process.

For Marywood University, a brand conscious college developing a new highway gateway sign. IDS worked to fulfill their vision with simple and quick sketch montages and then with full renderings to study both day and evening views. IDS can complete this work in a matter of hours and often as part of a live workshop approach.

Engineer – Prototyping Methodology

Design development often requires extensive exploration of materials, illumination and detail. IDS takes this process to the next level by incorporating prototyping directly into the design facilitation process. Starting with material samples, we expand into detail mockups and then full prototypes that serve as the model for final construction documentation.

For Syracuse University, working with the school and Architecture firm EDR, IDS started with a full sign vocabulary to determine the proper color, type and material approach. Extensive prototyping of details led to the fabrication of final prototypes and a refined document set.

Manufacture – Guidelines and Control

The secret to the IDS manufacturing process, and what leads to extensive ongoing projects over years, has been a tight documentation process built around manufacturing. We use our experience building, packaging, delivering and installing to inform our process, which we then distill in written guidelines and purchasing web sites. This ongoing approach results in greater efficiency and cost savings.

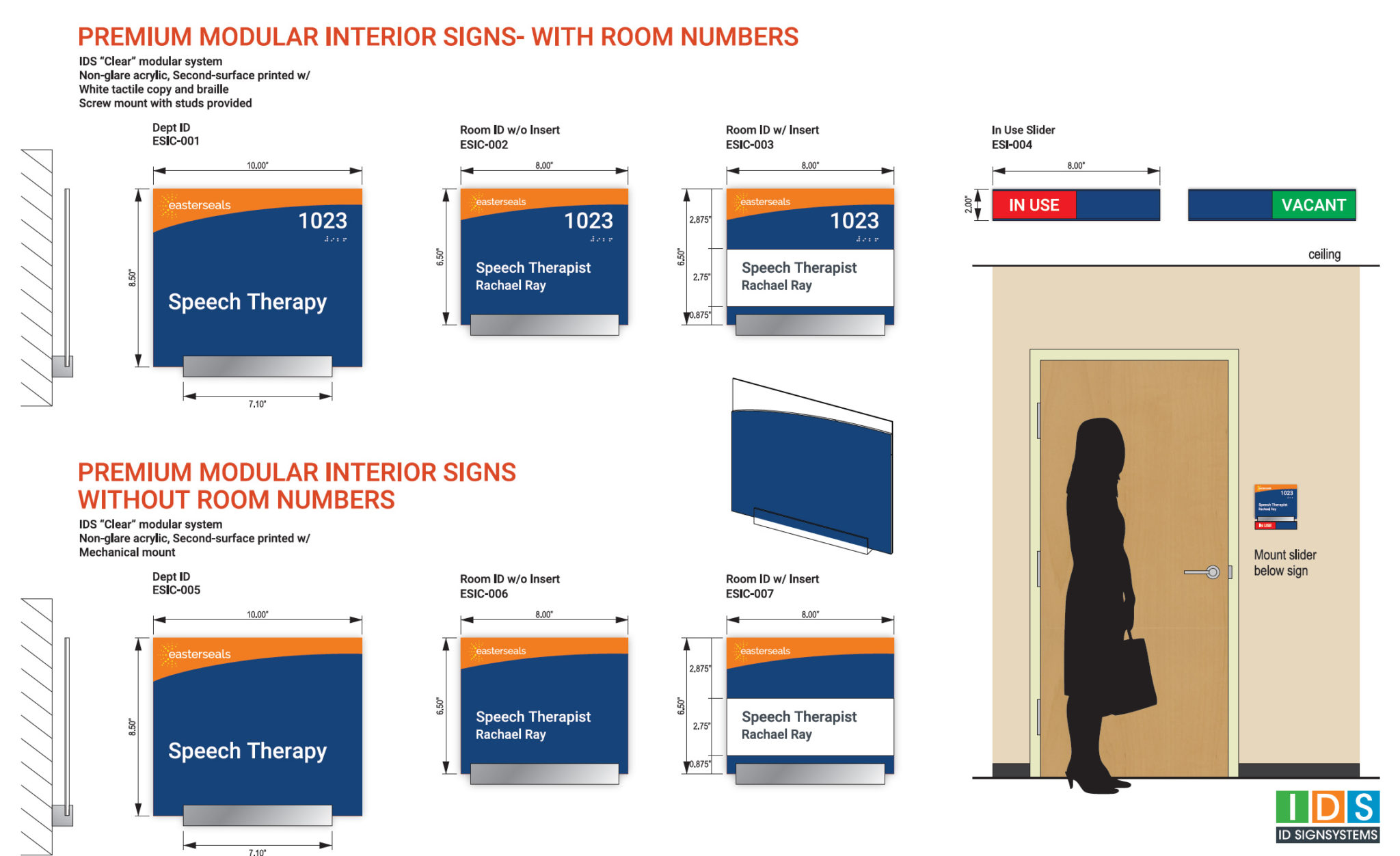

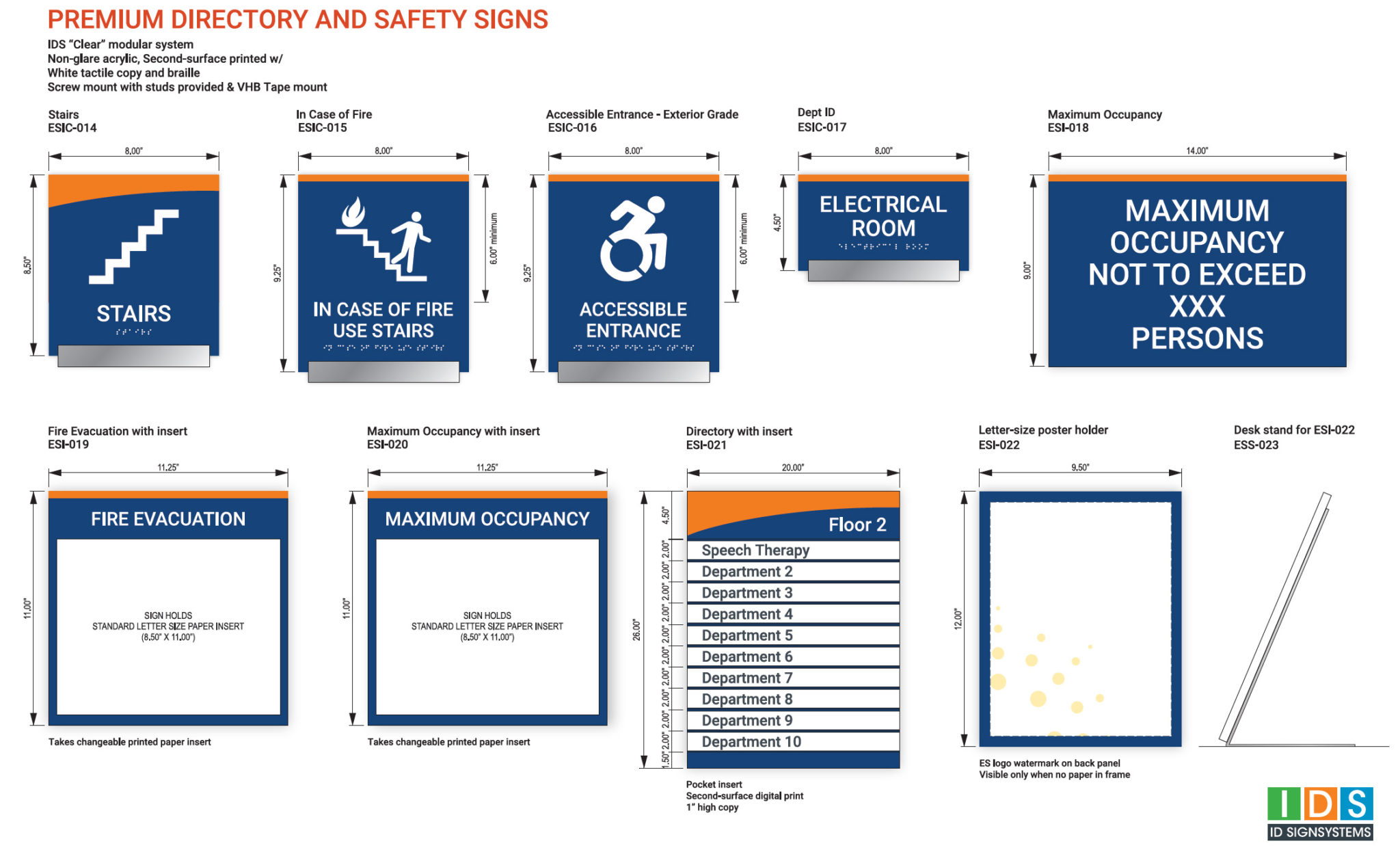

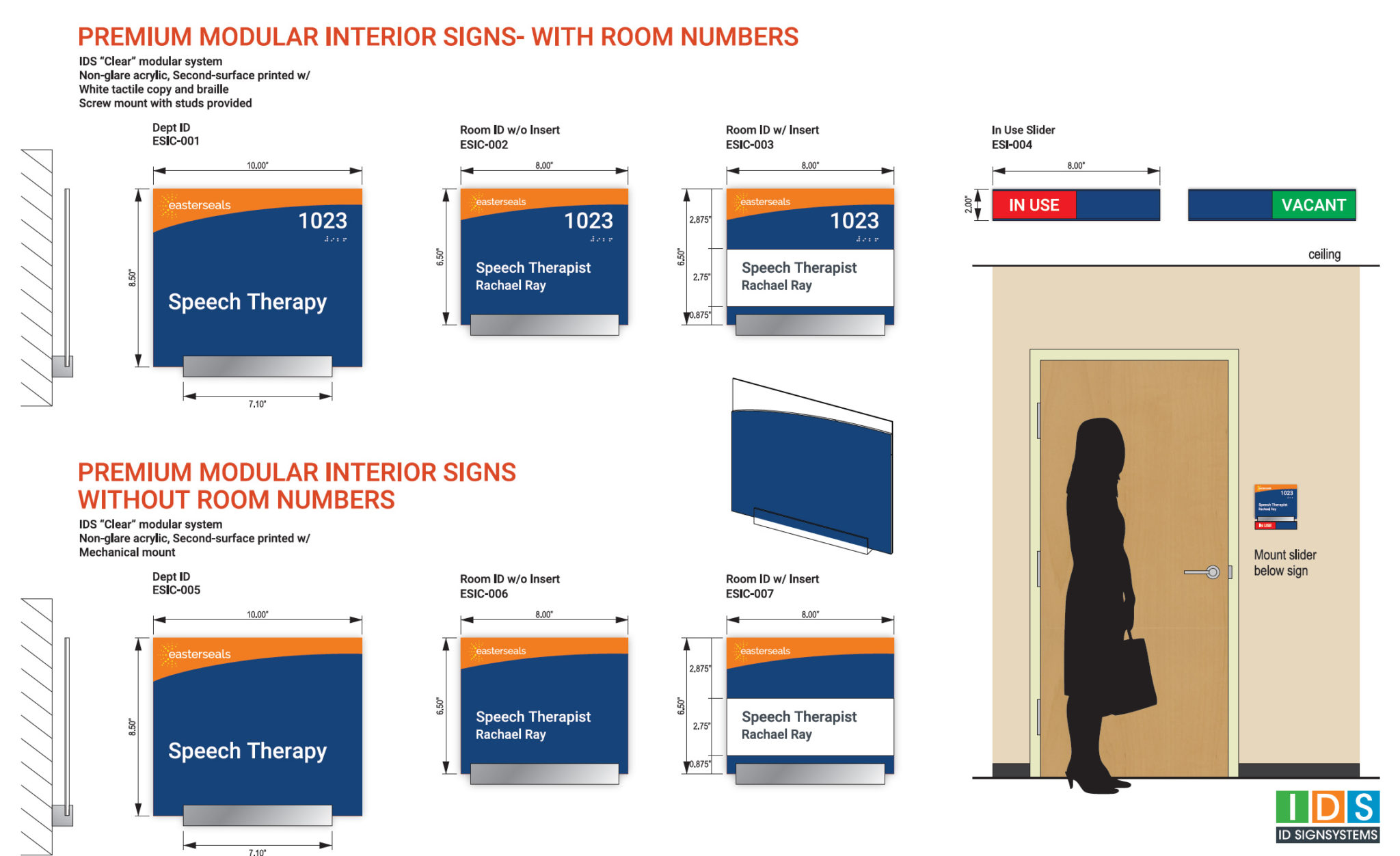

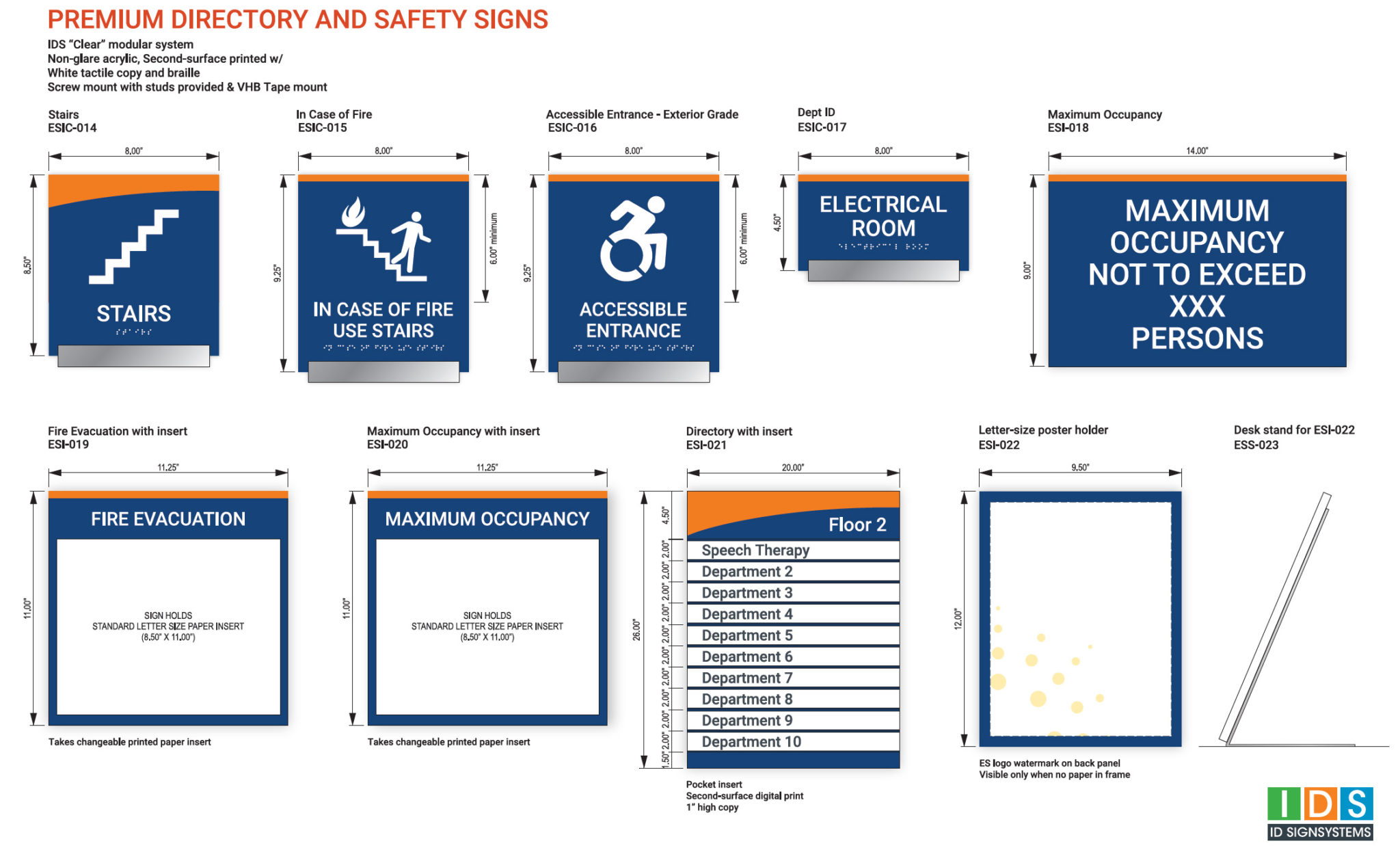

For Easterseals, IDS created a full set of guidelines and a purchasing website for a wide range of signs based on a consistent manufacturing and delivery approach. By coordinating sign selection with manufacturing, we can ensure greater cost savings and quality which is passed on to the client.

Manufacture – Guidelines and Control

The secret to the IDS manufacturing process, and what leads to extensive ongoing projects over years, has been a tight documentation process built around manufacturing. We use our experience building, packaging, delivering and installing to inform our process, which we then distill in written guidelines and purchasing web sites. This ongoing approach results in greater efficiency and cost savings.

For Easterseals, IDS created a full set of guidelines and a purchasing website for a wide range of signs based on a consistent manufacturing and delivery approach. By coordinating sign selection with manufacturing, we can ensure greater cost savings and quality which is passed on to the client.

Let’s Talk About Your Project